3T-GTEU/4T-GTEU

- A Turbocharged Twin-cam High-performance Engine

The 3T-GTEU, based on the

Over-Head Valve (OHV) 3T-EU engine, is the first twin-cam engine in Japan

fitted with a turbocharger. The 3T-GTE is the replacement for the

venerable 18R-GEU, and its development targets were to improve upon

performance, fuel economy and packaging.

Due to the high power that results from the addition of the twin-cam

cylinder head and the turbo, the thermal loading and combustion pressures

increased. As a result of this, for rotating and reciprocating parts,

vibration resistance strengthening measures greater than those for a

twin-cam were scrupulously applied.

In addition, with the increased engine speed and higher output due to the

turbo, an appropriate supply of fuel required at high engine speeds,

making it necessary to have a fuel system that can cover a wide range of

demands. As for the range required, from the very small injection quantity

required when idling, to the large injection quantity required at high

engine speeds, the appropriate injection volume is possible due to the

adoption of high capacity injectors and current control drive system.

The CT20 turbocharger is made by Toyota, and it has a maximum speed of

110,000 rpm. The CT20 is also used on the 2L-T diesel engine. A common

feature in both applications is that the shaft is only supported by the

bearing housing. The turbine housing and compressor housings, both of

these being items that decide the characteristics of the turbocharger, are

original to this application, and they have been designed according to the

performance targets of the 3T-GTEU.

The 3T-GTEU has adopted the knock control system and twin plugs (each

cylinder has 2 spark plugs). The KCS (See page xx-xx) achieves optimum

ignition timing, and the twin plugs shorten the flame propagation period;

both of these contribute to improved performance and fuel efficiency.

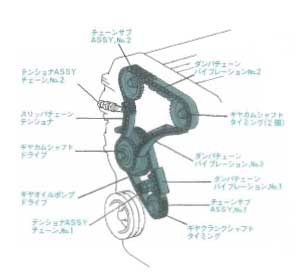

The camshafts of the 3T-GTEU are driven by a two-stage roller chain. This

arrangement, shared with the 4T-GTEU, was chosen to provide a reserve of

strength because the 4T-GTEU serves as the base for the 4T-GT race/motorsports

engine.

The development of the 3T-GTEU started with the aim of surpassing the performance of the 18R-GEU, and improving upon the fuel economy of its base engine, the 3T-EU.

Because development of the turbocharger took place alongside development of the engine, the technological strengths of each align. Many turbocharger prototypes were produced to achieve reduced turbo lag (the delay before the turbocharger begins to work), and to ensure that the turbocharger is effective at high engine speeds. From these, the optimum turbocharger, the one that achieved the target performance, was selected for production.

Putting aside the fact that those involved in development of the 3T-GTE hoped to see it used for motorsports, the 4T-GTE, with a 0.5 mm larger bore, was developed concurrently for limited production.

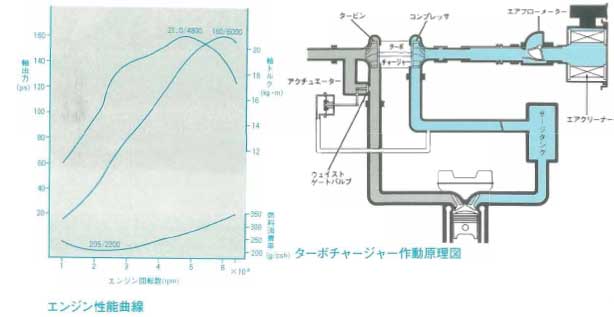

The turbine wheel of a turbocharger

is spun at high speed by exhaust gas, and it compresses the air supplied

to the cylinders using a compressor wheel mounted on the other end of the

same shaft. This is a form of supercharging, and it is used to obtain a

greater amount of performance than otherwise would be obtained from an

engine of a given displacement. The turbocharger makes use of the energy

in the exhaust gas that would otherwise be discharged into the atmosphere

as heat. Because the output of a large engine can be obtained with a small

engine, turbochargers are used also for engines such as those in sports

cars and race cars, where high power is desired in addition to the lower

weight and improved fuel economy.

System Diagram, Torque, Power and BSFC Curves

Next